Serveron TM1 Single Gas Online Dissolved Gas Monitor

Serveron TM1 Single Gas Online Dissolved Gas Monitor

The Serveron TM1 offers a breakthrough price/performance point in online DGA. For the first time, the benefits of online condition monitoring can be realised across the distribution transformer fleet.

The Serveron TM1 continuously monitors and reports hydrogen PPM Levels and can be programmed to alarm based on PPM Levels and/or Rate of Change (ROC), warning operators of potentially disruptive transformer faults and pending failures.

High reliability in a single gas DGA Transformer Monitor

With the TM1, Serveron have solved the various reliability issues commonly associated with many single gas DGA monitors.

No Membranes

The TM1 utilises a patented, solid-state hydrogen sensor that is immersed directly in the oil, eliminating membranes and the potential for rupture.

Circulate Oil

Without oil circulation inside the monitor, readings are unstable and show poor repeatability. The TM1 utilises a patent-pending, maintenance-free, forced oil circulation system.

No Hydrogen Consumption

For monitors that consume hydrogen during measurement, lack of oil circulation also means that hydrogen may be consumed faster than it can be replaced by diffusion, further reducing performance. In addition to circulating oil, the TM1 also utilises a non-consumptive hydrogen sensor.

Hydrogen Selectivity

Utilities monitor hydrogen because it is an excellent indicator of a wide range of transformer faults. Many “single” gas monitors are actually composite gas monitors whose hydrogen measurements are interfered with by contributions from carbon monoxide, acetylene and ethylene. These monitors measure only a very small percentage of acetylene and ethylene – in some cases less than 2%; not enough to indicate a fault.

More problematic is the interference from carbon monoxide which exists at much higher levels than hydrogen. Carbon monoxide masks changes in hydrogen, potentially delaying recognition of a fault condition. The TM1 is selective for hydrogen exclusively.

Temperature Control

Hydrogen readings vary with temperature even when hydrogen concentration in the oil remains unchanged, resulting in fluctuating readings that potentially delay recognition of an event. The TM1 utilises a patent-pending, thermally-controlled design that ensures stable results even under dynamic ambient or oil temperature conditions.

Download Serveron TM1 Brochure

Single gas DGA monitor

Hydrogen Diffusion Mechanisms

The TM1 uses three diffusion mechanisms for ensuring a representative sample at the measurement point for accurate and reliable hydrogen monitoring.

Convective currents generated by the transformer windings

Vibration further aids oil movement and diffusion

Most importantly, forced oil circulation inside the monitor

Gas-in-Oil and Rate-of-Change Trend Charts

Hydrogen gas-in-oil is an early indicator of incipient transformer faults. Continuous monitoring of hydrogen levels warns operators of potentially disruptive transformer faults and pending failures.

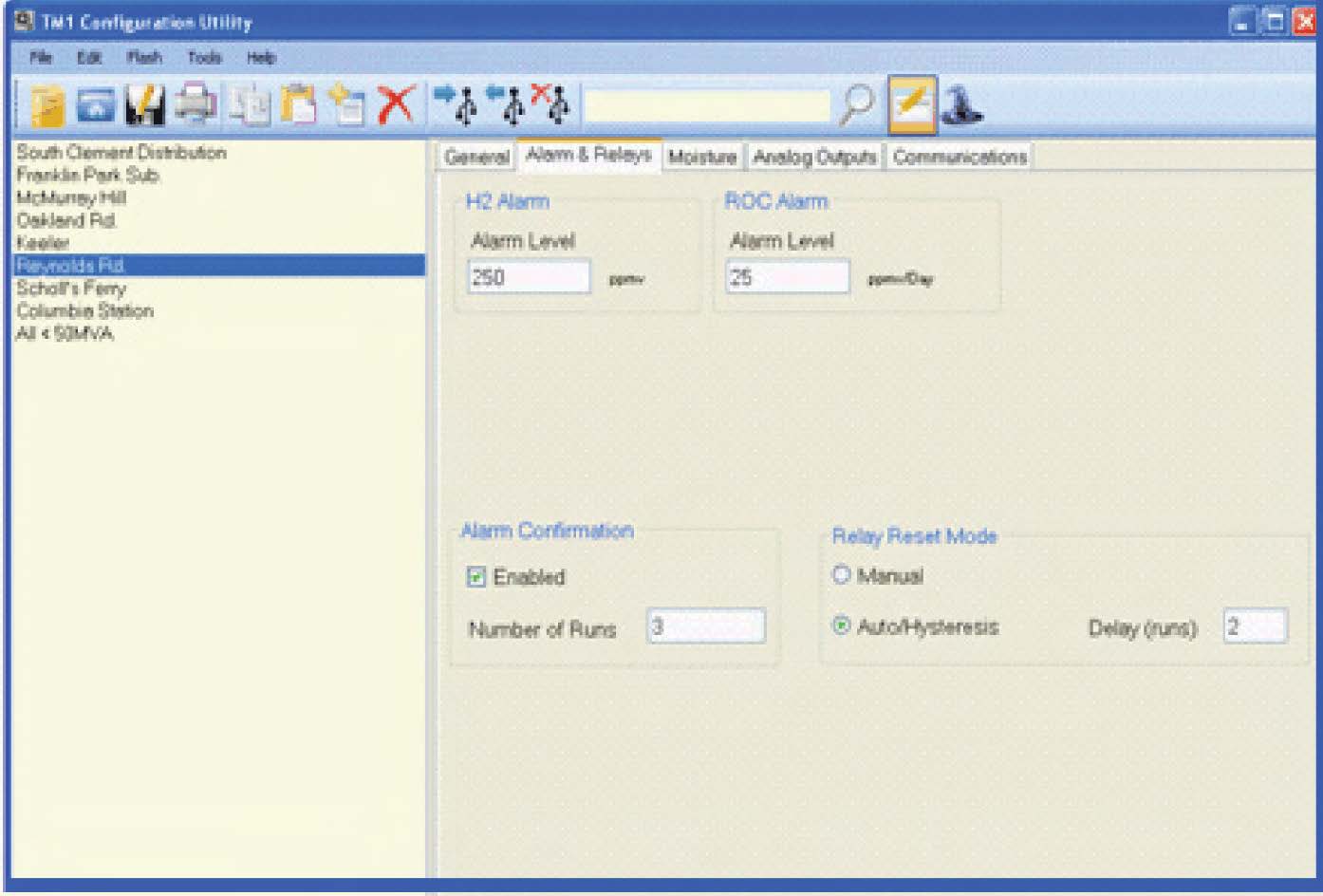

Configuration Utility

The TM1 comes with a simple, intuitive Windows based configuration software tool that enables users to quickly configure alarm set points, scale analog outputs, and set other communication parameters.

Features of Serveron TM1

Responds only to Hydrogen: no cross interference or composite measurements.

Rapid step change response facilitated by active oil circulation over the sensor itself.

Single Valve mount

Low Cost of Ownership:

No Membrane – directly immersed sensor

No Sensor replacement or recalibration required for life of monitor

No Consumables or routine service required

TM1 Options

Moisture-in-oil and oil temperature measurement.

Qualitrol provides utilities with the following services for our on-line DGA monitors.

Turnkey Installation Services including Serveron® TM1 deployment and TM View software user training

Serveron® Monitoring Service (SMS) offers the convenience of secure 24×7 access to all of your Serveron® DGA transformer monitor data from any Internet-connected Windows PC running our SMS software.

A variety of service plans to guarantee monitor operation over the long term

Talk to our team

Get more information on DGA monitoring