Free eBook and Webinar: Winding hot spot temp determination

Free eBook and Webinar: Winding hot spot temp determination

Qualitrol have made available another on-demand webinar. This one – Transformer Winding Hot Spot Temperature Determination – continuing on from last month’s webinar on Transformer Monitoring Basics.

This latest webinar outlines the developments in effective monitoring of a transformer’s internal temperature. Loading capability of power transformers is limited mainly by winding temperature. Knowing the exact internal temperature allows for better loading capability, longer asset life, hence greater revenues and lower asset replacement / repair costs.

What will you learn in this webinar?

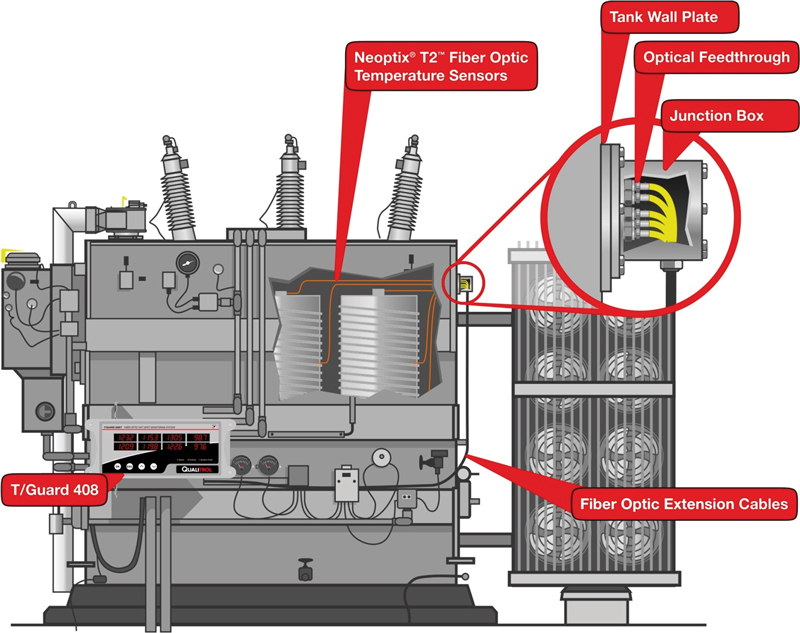

After reviewing basic data (e.g. insulation paper aging rate with temperature), the presenter conducts a comparison of the traditional means of measuring temperature (IEEE, IEC) with fibre optic sensor values in real time. It also covers the technology aspect (how it works) before examining field experience from a customer using sensors and how it relates to their overloading capability.

What are some of the risks of not determining the winding hot spot on a transformer?

Inaccurate calculation of the hot spots not only limits the transformer’s load but also cannot effectively evaluate the insulation paper aging or transformer loss of life. It is technically very difficult to evaluate loss of life without the use of direct, real-time measurements.

eBook Details: Fibre Monitoring for over a decade

The eBook covers some of the same basic information from the webinar, but takes it a step further, incorporating more detail and co-written with Manitoba Hydro of Canada, who have been monitoring 12 critical transformers using fibre optics since 1998.

Abstract: Loading capability of power transformers is limited mainly by winding temperature. As part of acceptance tests on new units, the temperature rise test is intended to demonstrate that, at full load and rated ambient temperature, the average winding temperature will not exceed the limits set by industry standards. However the temperature of the winding is not uniform and the real limiting factor is actually the hottest section of the winding commonly called winding hot spot. This hot spot area is located somewhere toward the top of the transformer, and not accessible for direct measurement with conventional methods.

Find out more about our range of Temperature Monitoring Systems below, or for more information;