Transformer Health Check: DGA Technologies

Transformer Health Check: DGA Technologies

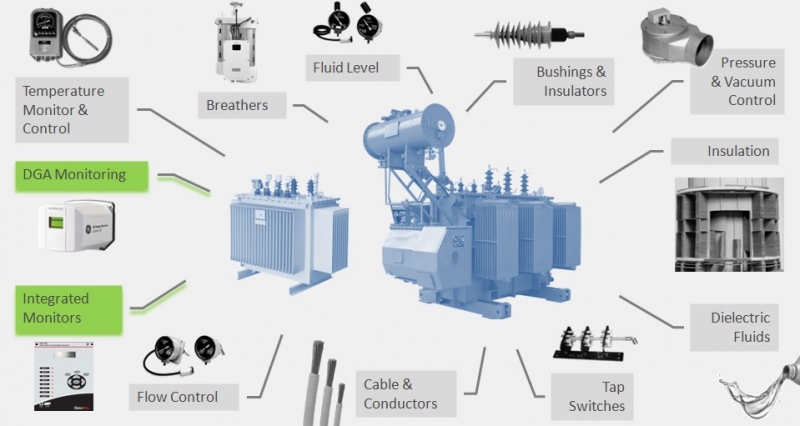

Transformer monitoring can assist in extending the life and performance of a transformer. Our CORE Transformer Optimisation approach - a fleet-wide "whole of life" methodology offers a broader evaluation of the transformer environment, addressing the interrelated planning, operational and risk factors that impact transformer performance and life. In doing so, it paves the way for better decision making, greater asset security and lower total cost of ownership.

Dissolved gas analysis (DGA) is a key part of this broader transformer monitoring application and is recognised as one of the most effective monitoring and diagnostic tools for asset owners.

Dissolved Gas Analysis - a key technology

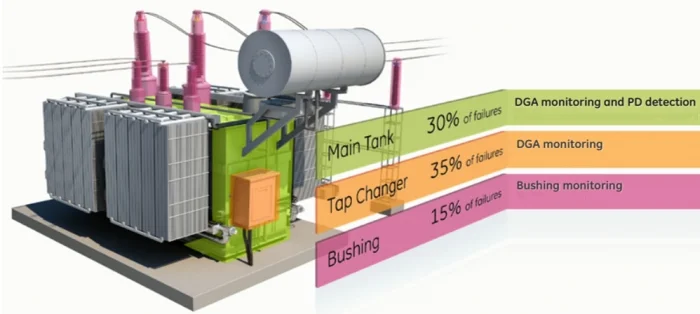

Most transformer owners rely on DGA via annual lab sampling while others utilise online DGA devices on problem assets or larger power transformers. The value of DGA is accepted as a means of periodic checks on transformer condition or post-mortem evaluation.

However, what has not yet occurred is the widespread use of online DGA monitoring across an entire fleet. Thus the continual monitoring and trending of this data for the purpose of providing real time alerts to impending issues, accurate diagnostics and better decision making. This is where the true value lies for DGA - not in post-mortem, but in prevention and management - helping to maximise asset availability and security, whilst minimising premature ageing and catastrophic failures.

DGA devices vary significantly in design (the number of dissolved gases measured) and cost, thus can be suited to a wide range of needs and budgets. Most instruments are designed for online measurement of the main tank, though there are some that can accurately measure dissolved gases in the tap changer or provide a portable "first response" solution.

Method

Sampling

Online: A closed loop system eliminating contamination from the external environment and prevents loss of gases. Standardised sample volumes.

Offline: Extraction via a transfer tube into a sample vessel, possibility of contamination due to exposure and fill volume inconsistencies.

Extraction

Vacuum: Extraction is achieved by placing the sample in a vacuum which is then compressed and measured by breaking the vacuum. Calculations are used to correct for incomplete extraction due to the solubility characteristic of the individual gases.

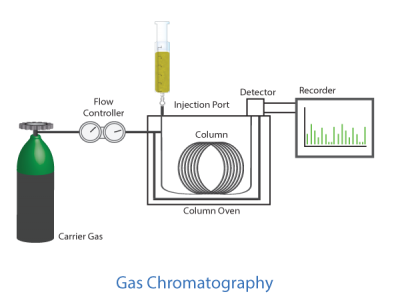

Stripping: A carrier gas is used to strip the sample gases out of the fluid, commonly used in GC applications.

Headspace: The headspace in a sample vessel of known volume is measured after the sample is added. Calculations are used to determine the initial concentration of the gas.

Analysis

Gas Chromatography (GC): Gas is passed through a column with a carrier gas towards a detector. Detection is based on the principle that different gases will travel at different rates.

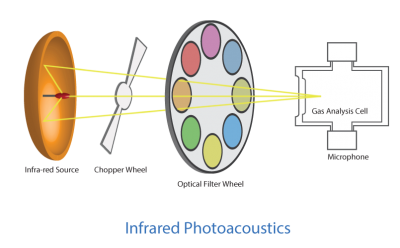

Photoacoustic Spectroscopy (PAS): Gas is exposed to infrared (IR) energy passed through a selected filter; the absorbed IR energy is converted to sound which is then recorded via a microphone. Detection is based on the principle that different gases will absorb different filtered energies.

The resulting signature profiles obtained in both methods are used to identify the specific gas/gases and subsequent concentrations in the insulation fluid.

As a diagnostic tool

Multiple methods of diagnosis have been developed shown in standards such as IEEE C57.104 and IEC 60599 which allow users to relate measured gas in oil concentrations to potential on-going or developing faults.

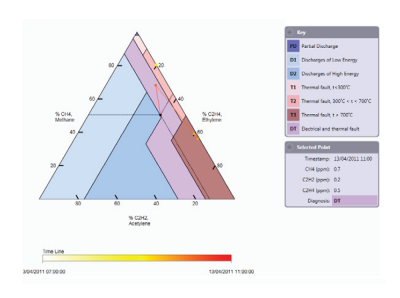

1. Duvals Triangle

Duvals triangle is based upon the relative percentage concentrations of methane, ethylene and acetylene plotted on a triangular coordinate system. It is a useful technique which produces a diagnosis regardless of gas concentration and has a proven low percentage of error. The six main fault zones are represented along with a DT zone indicating a thermal and electrical fault. The fault zones have been determined based upon a large sample of faulty transformer cases which have subsequently been inspected visually. This is a useful technique but is limited to detecting fault conditions when they have already formed, allowing a progression of an issue to be followed.

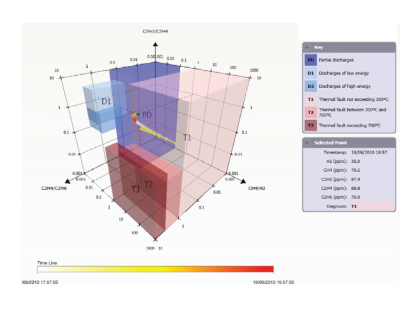

2. Rogers Ratio

Rogers ratio was developed from Halstead’s thermal equilibrium and Dornenberg ratios together with information gained from failed units. It was refined to 3 ratios which when compared, can be used to diagnose 6 possible faults. Rogers ratio method has the advantage that it is quantitative and is independent of oil volume and can therefore be used as a diagnostic tool on any oil filled transformer.

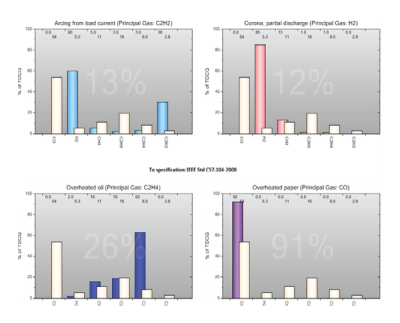

3. Key Gas Methods

The key gas method uses relative percentages of fingerprint gases to identify fault conditions. These fingerprint gases are defined in IEEE C57.104 and based on those that are typical or predominant at various temperatures. Using this definition results in characteristic charts which represent relative gas concentrations relating to four general fault types. It is a frequently used technique which provides an adequate approximation of the transformers condition. This method can however result in a high percentage error and should be used with other techniques for best results. It does allow progression of developing faults to be highlighted and monitored.

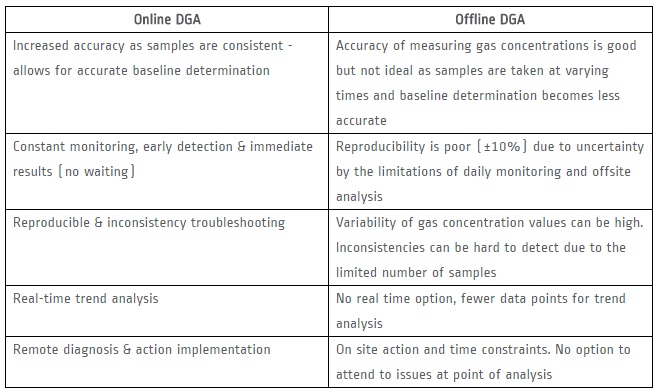

Online vs Offline