Transformer Life Extension

MIDEL fluids can have a positive impact on the issue of paper ageing, delivering:

Longer life for cellulose insulation at standard temperatures

The option to run transformers at a higher temperature for standard lifetime

The benefit of a higher power output or a smaller footprint by running transformers hotter

Using MIDEL ester transformer fluids can potentially significantly extend the life of cellulose insulated transformers. Alternatively, transformers can be operated at a higher temperature with MIDEL fluids, while retaining the same lifetime they would have had with mineral oil at standard temperature.

The cellulose paper insulation in a transformer is the main contributor to the lifetime of the equipment, since the paper is present to provide both electrical insulation and mechanical strength. If the paper degrades to the point where it becomes brittle then the transformer will lose the ability to withstand faults, such as short circuits and in the worst case the windings can collapse if the paper is weak enough.

Factors Affecting Cellulose Ageing

There has been a large amount of research looking at the factors which affect cellulose ageing in mineral oil. It concludes that the key parameters affecting rate of ageing are moisture and temperature. If moisture content in paper doubles, transformer life expectancy is immediately halved. Similarly, a thermal increase of just 10°C will lead to cellulose lifetime being cut by over 50 per cent.

Studies have also been carried out to compare the ageing rate of cellulose immersed in ester fluids with those in mineral oil. It was proved that ester-based transformer fluid has a very positive influence on ageing and the updated standards IEC 60076-14:20132 and IEEE C57 154:2012 have appendices which summarise the findings.

READ MORE:

ISO 55000 + ESTER FLUIDS

Lifetime Extension with Ester Fluids

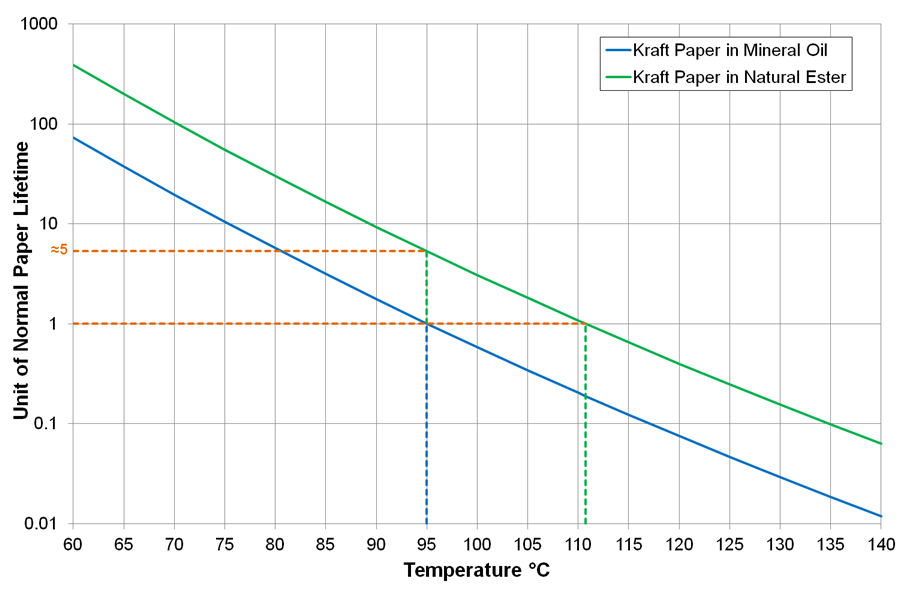

As part of the new standards a unit life vs. temperature chart has been produced, for both kraft paper and thermally upgraded paper. This summarises the findings of a large number of studies conducted with natural ester fluids and indicates that at an operating temperature of 95°C the lifetime for kraft paper could be as much as 5 times longer than in mineral oil. Alternatively to get more power from the transformer, without additional loss of life, the ester unit life chart indicates that kraft paper can be run 16°C hotter.

Unit Life Chart for Kraft Paper

Extending Life Expectancy with MIDEL Esters

A further study was carried out by Weidmann Electrical Technology and M&I Materials over a period of 12 months.

It demonstrated that both MIDEL 7131 and MIDEL eN 1204 have the same ability to slow the ageing rate of cellulose as other natural ester products. This proves their capacity to significantly extend transformer life expectancy when compared with mineral oil. This is due to the interaction between the MIDEL esters and the water released by the cellulose as it ages.

If mineral oil is used, this moisture remains in the paper and accelerates the ageing rate, whereas with MIDEL transformer fluids the water level is reduced. This ensures the paper remains drier and maintains its strength for a much longer period of time.

All of these studies support the view that MIDEL fluid filled transformers with cellulose insulation will enjoy an extended transformer life when compared with equivalently-rated mineral oil transformers. Conversely, the same transformers should be able to run up to 16°C hotter with Kraft paper or 20°C hotter with thermally upgraded paper, without compromising the transformer’s working life.

Get more transformer life

Choose a MIDEL transformer fluid