Replacing metals with composites in demanding applications

Replacing metals with composites in demanding applications

Reduce maintenance, capex, opex and extend life

The operating conditions common to the Oil and Gas sector can readily be referred to as arduous. Asset owners regularly face challenges from these extreme environments, such as ensuring equipment is maintained and in optimal working condition.

It is in these circumstances that composite materials really prove their worth. Composite materials can provide a low maintenance and hard wearing alternative to stainless steel, aluminium and other similar materials.

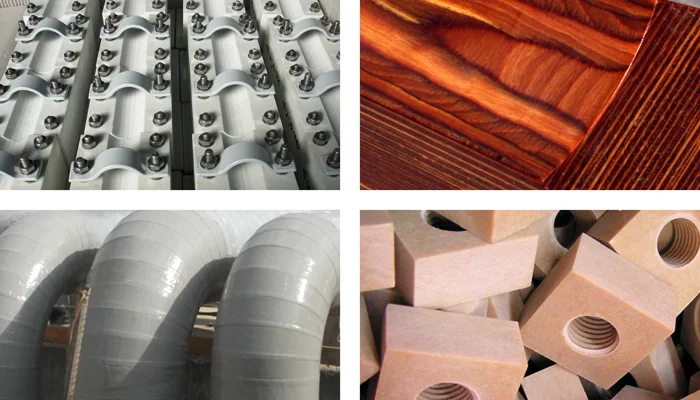

Some examples of composites in action, including as structural supports, pipeline cladding, and in fastening systems.

Demanding applications

Below are some of the key requirements Insulect regularly addresses through the application of composite materials in place of metal:

- Chemical and corrosion

- Mechanical strength

- Water permeability

- Temperature extremes

- Thermal flow

- Lightweight

- Electrical resistance and strength

The composites materials advantage

Insulect has partnered with Rochling - one of the leaders in the world of engineering plastics - allowing us to provide our customers with a wealth of application knowledge and the custom development of materials to suit the many demanding of applications.

Rochling have a wide range of materials that are designed around specific applications - electrical, thermal, mechanical, chemical or combinations of these - to ensure they meet the needs of the end user and deliver substantive advantages.

Discuss your needs

Our engineering materials team are here to evaluate your application with you and determine what materials would be best suited. Give us a call today to find out more.